Lightweight - 200t

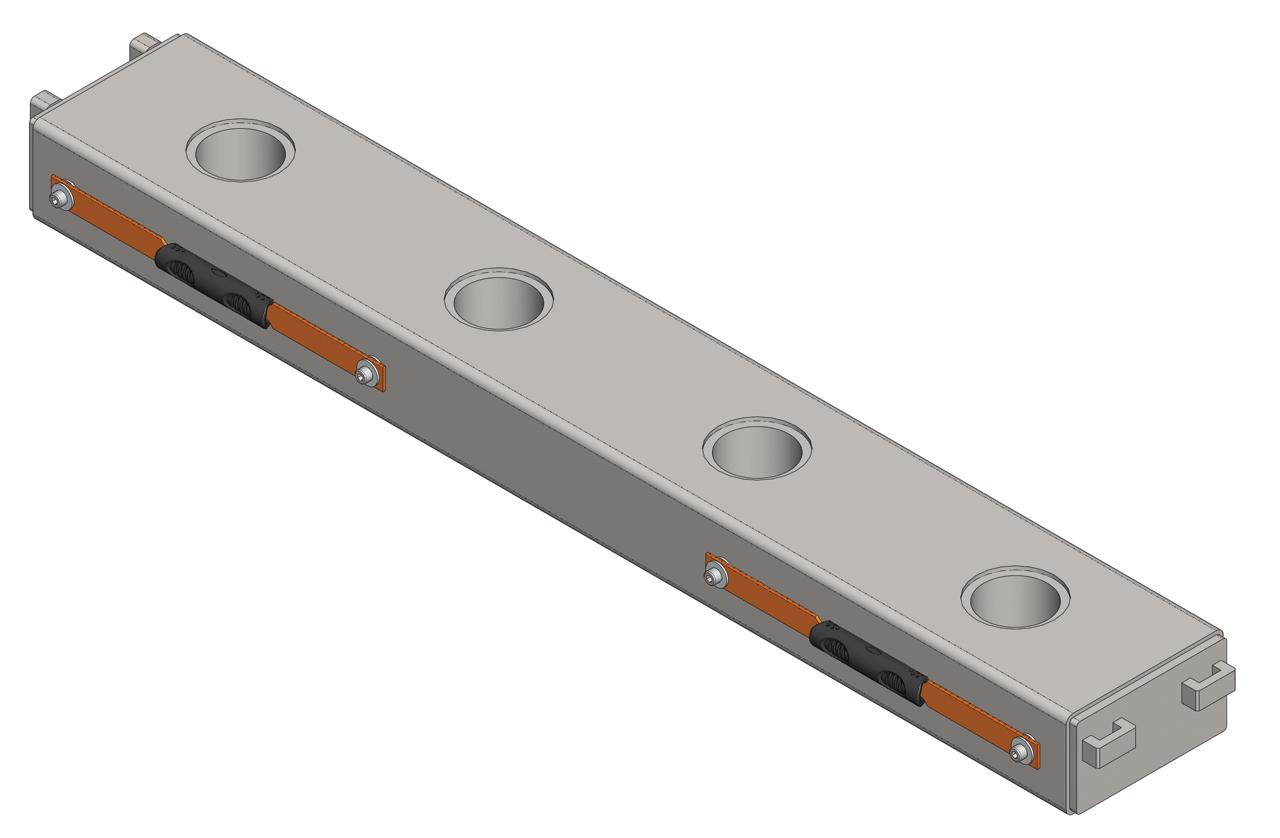

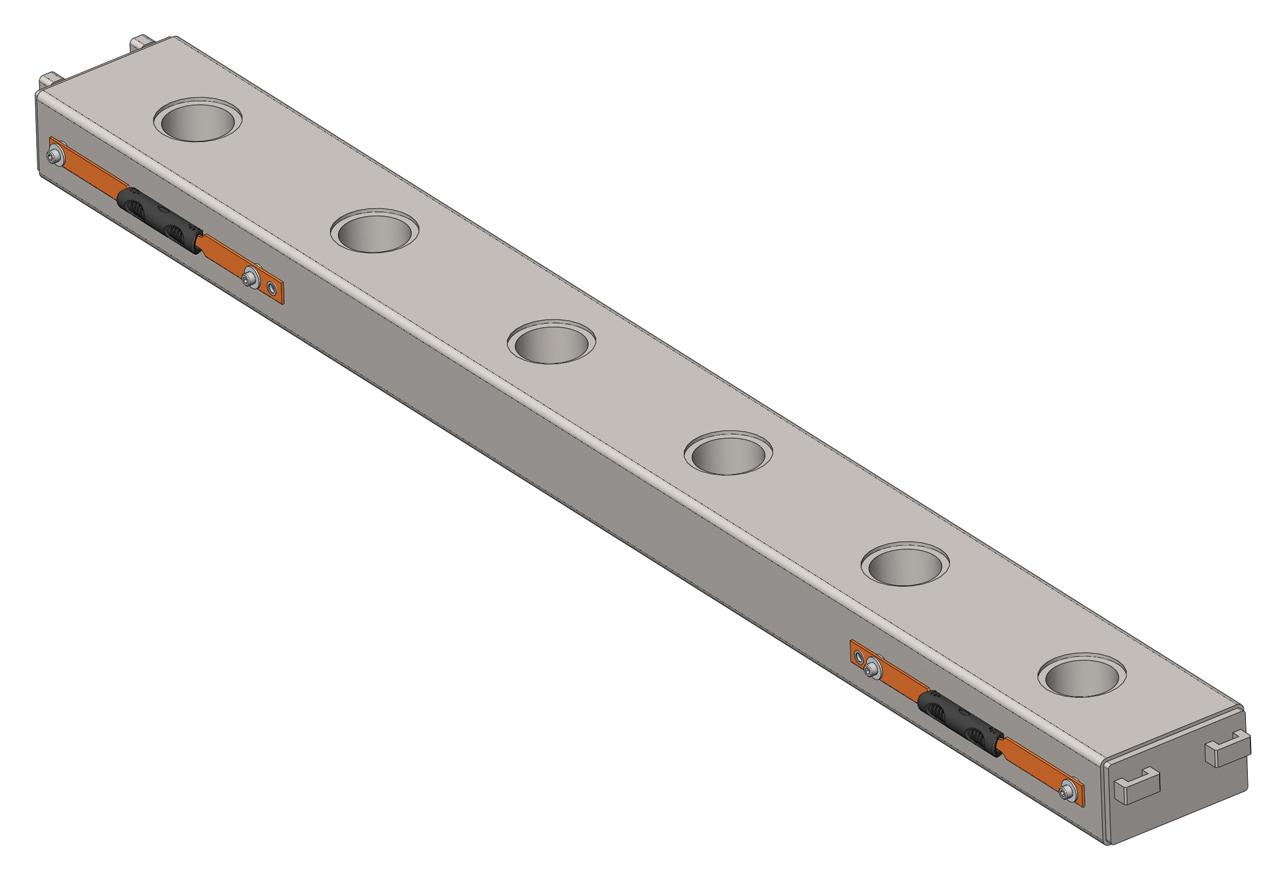

Holmatro’s Lightweight Skidding System is built of extremely lightweight components, so it can be easily carried, handled and positioned by one or two persons without the need for a forklift or the use of extra equipment. The maximum capacity of the system is 200 tons, assuming two skidding units are used. The total construction height is just 56 mm (2.20 inches).

The lightweight system starter kit includes 8 tracks, 2 beams of 1 meter, 2 beams of 1.8 meters, 2 push-pull units, 2 push-pull brackets, 4 hoses, a hydraulic Twin pump on a trolley and a storage frame.

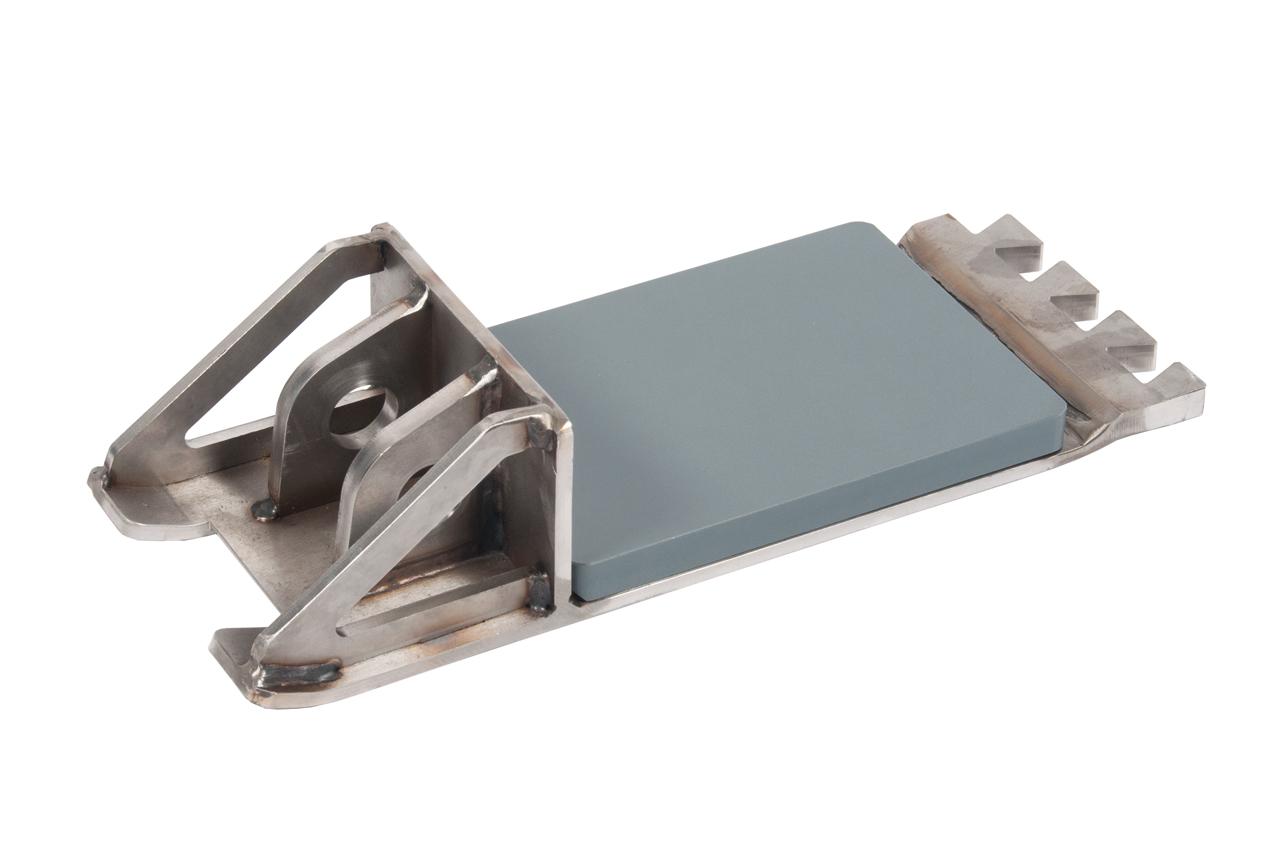

The tracks are easy to connect to each other by means of a click system (no bolting). Stainless steel beams are placed in the tracks. With a handle on the push-pull unit the push or pull direction of Holmatro’s lightweight Skidding System can be switched in a split of a second. The return line of the push-pull cylinders is internal, which significantly reduces the chances of this being damaged. Because the supply and return couplers are positioned next to each other on the back side of the cylinder due to the use of the internal return line, the hoses needed for ingoing and outgoing oil are of equal length. The Skidding System is driven by a powerful hydraulic twin (split flow) pump.

Holmatro has developed extra high beams (optional) for situations where the contact surface of loads do not entirely fit on the front side of the push-pull unit. These form fit the standard beams, so that the total weight is optimally distributed across the entire system.

Features & benefits

- 200-ton capacity (2 X 100 t)

- Low construction height; total height is 56 mm (2.20 inches)

- Efficient when there is limited insertion space - Lightweight components with optimally placed grips

- Easy to carry, handle, position and assemble by one or two persons (no forklift needed)

- Reduces the physical burden

- Maximum performance at a minimum weight - Modular system

- Easy to adapt to different load sizes and projects

- Plug and play; easy to assemble without the use of extra equipment - Push-pull cylinder with equal capacity for both pushing and pulling

- Ability to push or pull the load into position, instead of only pushing

- Accurate control in both directions - Change of direction by the use of a handle; push or pull direction can be switched in a split of a second

- Internal return line in push-pull cylinder

- Reduces the chance of damage to the line

- Equal hose length for ingoing and outgoing oil - Safe; integrated safety features in the push-pull cylinder for protection against overpressure

- High beams form fit the standard beams; in case of loads whereby the contact surface not entirely fits on the front side of the push-pull unit

- Total load is optimally spread across the entire system - Sliding pads with extremely low friction coefficient; low sliding resistance between tracks and beams

Standard supplied with

- Pump trolley; easy to move the pump

- Rack for storing the tracks