Innovation

Groundbreaking product innovations

On 19 May 1967, we started out as a trading company and quickly grew into a production company manufacturing pumps and jacks. In the mid-1970s, Holmatro’s growth accelerated partly due to the introduction of lighter and compacter rescue tools based on high-pressure hydraulic jack technology. We introduced our first rescue tool, the cutter, at the 1977 Europort expo. Two years later, we launched the first complete range of rescue tools onto the market, which was a revolutionary improvement.

In the spring of 2003, Holmatro launched a new industrial cutter product range for recycling and demolition. The arrival of our hydraulic cutter product range was a huge improvement in terms of speed, safety, and user-friendliness in this market.

In the spring of 2003, Holmatro launched a new industrial cutter product range for recycling and demolition. The arrival of our hydraulic cutter product range was a huge improvement in terms of speed, safety, and user-friendliness in this market.

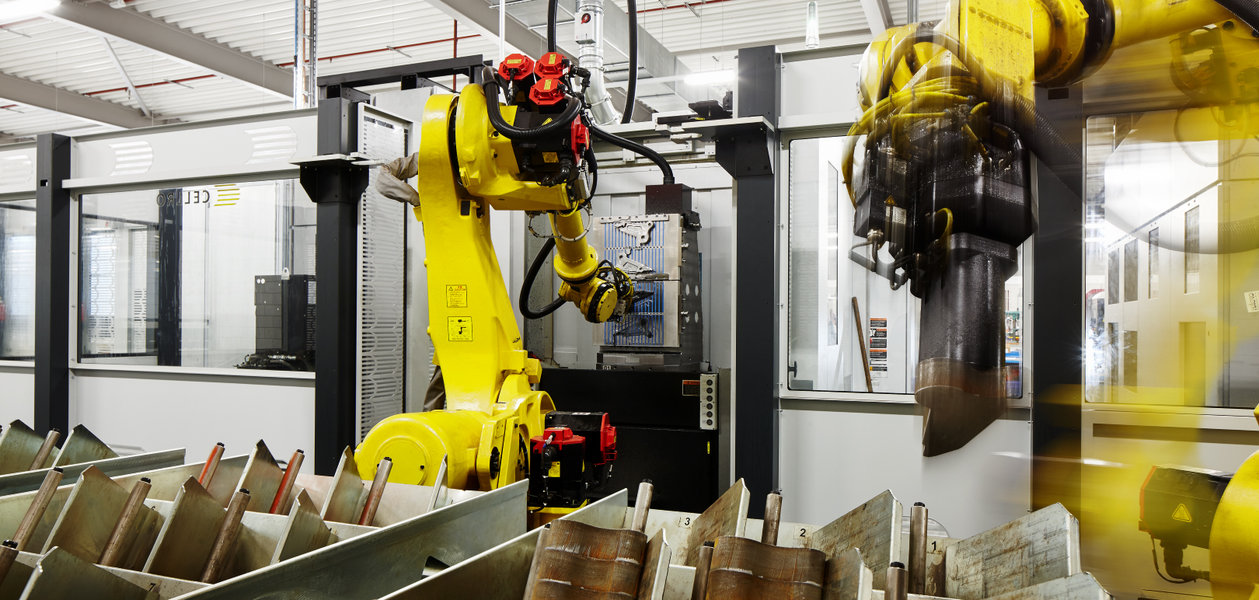

In order to maintain our leading position as a specialist in high-pressure hydraulics, we continuously invest in product development. Not just the standard high-pressure hydraulic tools, such as cylinders and pumps pass in review of our engineering teams. We also work hard on developing more complex and for the most part customer-specific solutions. By adding our product knowledge to the customer’s practical knowledge , we are capable of combining that experience from the market with the latest technology. The results are revolutionary: extremely user-friendly hydraulic systems to work faster, with more control, and safer.

Social innovation and business projects

The development of meaningful products and the use of groundbreaking technology leads to continuous investments in social innovation and business projects in the fields of ICT, Operations, and Business Intelligence, etc. By continuously improving our work method, we are able to lay down the standard for hydraulic tools and systems.

Sustainably building towards the future

That innovation is important to Holmatro in the broadest sense of the word, is also shown by the expansion of our existing headquarters located at the Zalmweg in Raamsdonksveer. The focus of the expansion is on far-reaching sustainability and following the guidelines for the prestigious BREEAM-NL certification. This becomes evident in the choice of materials, a glass facade with hundreds of integrated solar cells, the installation of a windmill, and 1,100 solar panels on the roof of the production halls. This means that the location can generate 50% of its energy needs, which makes us the first production company to achieve this in the region.

That innovation is important to Holmatro in the broadest sense of the word, is also shown by the expansion of our existing headquarters located at the Zalmweg in Raamsdonksveer. The focus of the expansion is on far-reaching sustainability and following the guidelines for the prestigious BREEAM-NL certification. This becomes evident in the choice of materials, a glass facade with hundreds of integrated solar cells, the installation of a windmill, and 1,100 solar panels on the roof of the production halls. This means that the location can generate 50% of its energy needs, which makes us the first production company to achieve this in the region.