Technical guidance hydraulic (lifting) tools

The power of hydraulic driven tools lies in the fact that you can move a large load by fluid under high pressure 700 Bar / 10.000 Psi. Hydraulic cylinders, also referred to as jacks, bottle jacks, presses, small presses, small bottles, pumps, or small pump jacks, find application in the movement of heavy objects. This can be done by lifting, lowering, pushing, pulling, pressing, spreading. Our hydraulic cylinders function on the principles of high-pressure hydraulics, enabling them to withstand operating pressures of up to 700 Bar or 10,000 Psi. The hydraulic pump directs hydraulic oil into the cylinder, leading to an increase in pressure within the cylinder. The hydraulic pump forces hydraulic oil into the cylinder, causing the cylinder's plunger to be pushed out, enabling you to lift, lower, push, pull or spread.

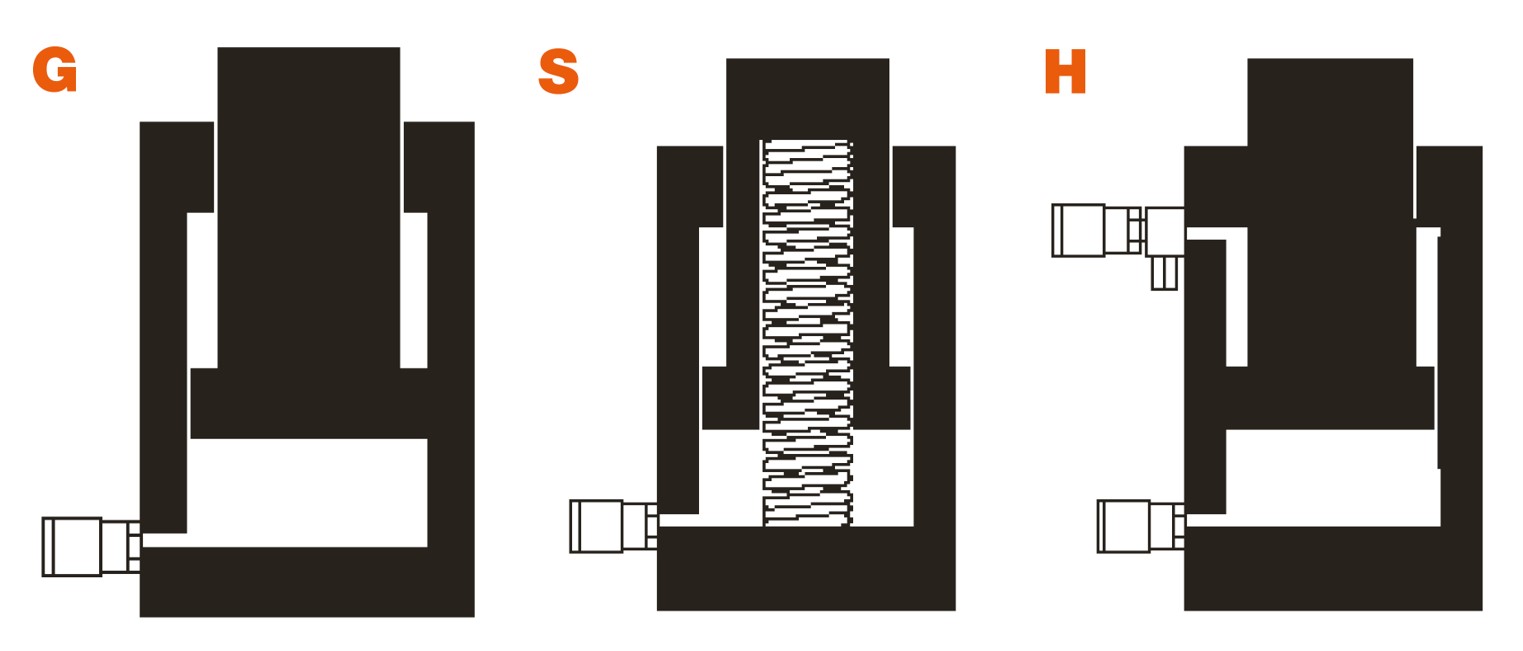

Our 700 Bar / 10.000 Psi cylinders are available in 3 different return types:

Gravity return (e.g. HJ50G30)

Return of the plunger by means of the load or another external force.

Spring return (e.g. HGC25S25)

Return of the plunger by means of a spring integrated in the cylinder.

Hydraulic return (e.g. HAC50H10)

Return of the plunger by means of hydraulic pressure. A.k.a. ‘double-acting’ cylinders.

Basic knowledge of Holmatro industrial hydraulic Tools

1. Recommended total cylinder capacity

In connection with various uncertainties, we always recommends a system with sufficient extra capacity:

• The exact weight of the total load

• The spreading of the load among the cylinders

• Possible moving of the load in case of calamities

2. (F)orce of a cylinder = P X A

The force (capacity) generated by a cylinder is equal to the hydraulic pressure (P) multiplied by the effective pressure area (A) of the plunger.

3. Minimum effective tank volume of pump =

(oil volume of cylinder 1 + 2 + ....) x 1,2 (20%)

4. Required operating speed =

(oil volume of cylinders 1 + 2) ÷ pump output

DO YOU FEEL THE PRESSURE TO WORK SAFE? USE YOUR BRAIN!

Believe in creating a safe and neat work environment

Read the instructions and use the equipment as specified

Always work with Personal Protective Equipment

Inspect your equipment; scheduled maintenance and certification is required

Never work with damaged equipment!

Correct & periodic maintenance can prevent unnecessary damages, costs, and unsafe situations.

To make sure you are working safe with high-pressure hydraulics, have your tools regularly tested & serviced:

• At least once a year

• With use of dynamic testing

Holmatro’ s years of experience has learned there is only one correct way to determine if a hydraulic system is safe to use: dynamic testing. Dynamic testing involves simulating a maximum use situation of the hydraulic cylinder over the complete stroke in a controlled environment. By doing so, any hidden defects can be identified early on, ensuring the reliability, safety, & lifespan of your tools.

• This testing method is specifically designed for high-pressure hydraulics exceeding 500 Bar / 7.250 Psi

• With a safety margin of 105% over the system's maximum pressure.

Which items in your hydraulic system require periodic maintenance, in order to work safe?

• Hydraulic pump: serves as the motor of your system; regulates the oil flow and working pressure.

• Hose: The hose transports oil from the hydraulic pump to the cylinder(s). Proper maintenance of the hose is essential to prevent leaks or ruptures and ensure the safe flow of hydraulic fluid.

TIP: make sure to always have a pressure relief tool available with you!

• Cylinder: The hydraulic cylinder is the primary tool used to lift, push, pull, wedge high tonnage and exert force with a small surface area. Regular maintenance of the cylinder is vital to keep it in optimal condition for a safe and efficient operation.

The whole hydraulic system functions under high pressure (> 500 Bar / 7.250 Psi ). The system components may Bare both visible and invisible malfunctions. Dynamic testing, which simulates maximum use situations, is a key aspect of Holmatro's approach to ensure the safety and reliability of the hydraulic system.

Safety data sheets

Unprofessional use of high-pressure hydraulic tools occurs on a regular basis. Our safety sheets list all the dos and don’ts for working with hydraulic lifting tools in a straightforward and conveniently

organized manner. These are indispensable in every workplace where hydraulic tools are used.

Download our safety data sheets

The Holmatro test team & working safe

Working with 700 Bar / 10.000 Psi is not to be taken lightly. The Holmatro Test team demonstrates and explains the risks of working with high-pressure hydraulics in an easy, recognizable way.

Toolbox meetings

A Toolbox meeting is a periodic meeting intended to improve daily safety at work, based on a specific

topic. We help you understand and recognize the risks related to high-pressure hydraulics, with on- and offline tools. Not only to help keep your employees safe, but also meet your legal obligations. Feel free to contact us for more info.