New Car Technology

What is cutting performance?

As a rescuer you want to work with a cutter that delivers the best cutting performance. If you are mainly active in the field of vehicle rescue, this should be a cutter performing optimally on (new) cars. But what is actual cutting performance? Is it the maximum force you find in the technical specifications? Is it reflected by the cutter classifications of the international EN 13204 and NFPA 1936 standards? Or are there any other determining factors?

Maximum force

This is a theoretical, calculated value. If you would have a cutter with blades made of paper this value would remain the same. So it does not say anything about real cutting performance.

Cutter classifications

Both the EN 13204 and NFPA 1936 standards have drawn up performance rating systems for hydraulic cutters, which are used by independent certification authorities such as UL and TÜV. The classification a cutter gets is based on its capacity to cut a certain number of material profiles in different shapes and sizes. Although this is an accurate and objective way of measuring cutting capacity, it does not give you an indication of a cutter’s performance on (new) vehicle construction.

Actual cutting performance

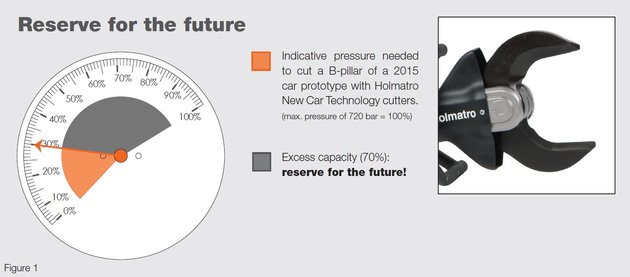

At Holmatro we believe that the best rescue tools are developed on the basis of practical application. So when it comes to vehicle extrication you need a cutter that performs optimally on (new) cars. Our New Car Technology cutters are specially designed to deal with the latest vehicle construction. Extensive testing on the latest prototypes shows they even have lots of capacity left for the future (see figure 1). Their superior cutting performance on modern vehicles has got nothing to do with maximum forces or cutting classifications. It’s all about smart tool design.

1. New Car Technology blade design

These characteristic U-shaped blades have two advantages:

- They can surround the wide pillars of modern cars

- They automatically pull the material into the cutting recess, close to the i-Bolt, which is the strongest point of the cutter. This results in a superior cutting performance.

2. Optimized cutting edge

Durability meets performance. We’ve optimized the cutting edge for a long blade life and a superior cutting performance on modern cars.

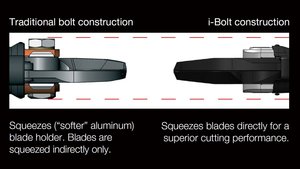

3. i-Bolt

The i-Bolt is a flat central bolt construction squeezing the blades together directly and more tightly, which minimizes blade separation. The result is a better cutting performance. It also gives you the advantage of better access into narrow spaces.

4. High-grade steel blades

High-pressure hydraulic tools can generate extremely high forces. That’s why our tools are constructed of the highest quality materials. This means you can use them for the most challenging applications, over and over again.

Excess capacity

Holmatro NCT cutters cut the high-strength materials and reinforced pillars of modern vehicles far more efficiently and at a lower working pressure than possible with general purpose (GP) type blades. In other words: They still have enough excess capacity to deal with future car constructions.

Watch this video showing the excess capacity of Holmatro NCT cutters

Proven performance

We keep testing our NCT cutters on brand new car prototypes. This is possible thanks to our close contact with various car manufacturers.

Below videos show the performance of a Holmatro NCT cutter on a new model car.

Opel Meriva B-pillar top cut:

Opel Meriva B-pillar bottom cut:

Try for yourself

Lighter and more ergonomic than ever, combined with the best results on modern vehicles: this summarizes our new 5000 series of New Car Technology cutters. Of course, the best way to judge them is to test them yourself. This will surely get you convinced of their outstanding performance on new cars. Contact your Holmatro dealer or sales representative now for a demonstration on location.