Hydraulic Cutter Performance – A Breakdown in Selecting Rescue Cutters

As a rescuer, you want the best performing, most reliable tools. You need to be able to free entrapped patients as efficiently and safely as possible. Comparing modern hydraulic rescue tools can be a daunting task, so how do you make the right choice? In this blog we will look at cutting tools specifically.

First, rescuers all want the strongest cutter. Next, they want to be able to cut anything they think they will ever encounter on a rescue call.

Easy enough, right? Just choose the tool with the highest cutting force and the highest cutter classification. Well, not quite.

Cutting Force

With today’s technology, the highest cutting force will be somewhere around 400,000 lbf / 181 t. But wait, if we look closer, those are merely theoretical forces. That means they are not measured, they are calculated. These forces are determined by each manufacturer, using calculations based on the geometry associated with their tool materials and design. The number is a product of the blades and the components that connect them to the hydraulic piston. Very scientific, but in reality the outcome may tell you very little about how well the tool will cut the roof pillar of a vehicle.

High-grade steel blades vs. wooden blades: Both cutters have the same theoretical cutting force, but don’t deliver the same cutting performance.

Cutter Classification

Ok, then we will use the classification of the cutter. The governing bodies of your region have adopted standards to test hydraulic rescue tools, e.g. the American NFPA 1936 standard or the European EN 13204 standard. Cutters are classified as to their actual ability to cut materials prescribed by the standards. In general the materials are round bar, pipe, square tubing, flat bar, angle iron and rectangular tubing. Each entity chooses the hardness and size of the material for each category. A cutter must make a prescribed number of successful cuts on a material to earn a score. Perfect, we will choose the cutter with the highest classification or score. But wait, the shape, construction and metals do not necessarily represent those found in modern vehicles. If we were cutting up a building, it would be a great way to choose, but we are cutting cars. Classifying entities are currently working to help us with testing criteria more closely related to vehicle construction, but that is a very difficult thing to do. The differences between auto manufacturers and each of their models is huge and ever changing.

An excellent score on cutting round bar is no guarantee for an outstanding performance on (modern) vehicle construction. Always test a cutter on the application it will be used for.

Surrounding Cuts

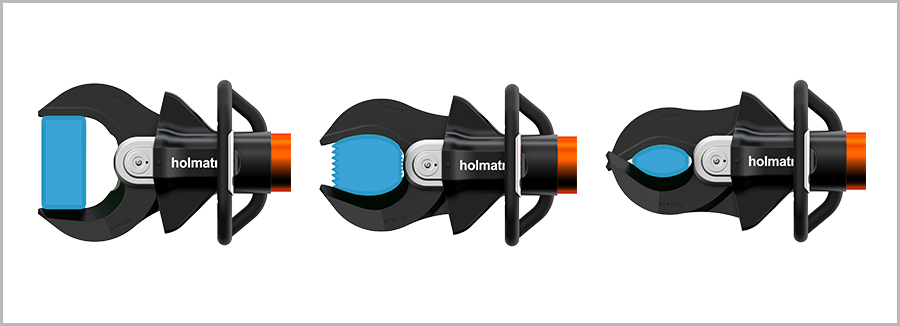

Rescuers working with motor vehicle entrapment cut a lot of round and rectangular shaped objects. Curved blade cutters are generally more successful and efficient for this. They surround the material and pull the cutter towards it, so the material ends up close to the strong “notch” or the area closest to the large hinge bolt, which is the strongest point of the tool. This allows the cutter to direct the largest amount of its energy into the material causing it to fracture. When cutting the high strength steel alloys on modern vehicles this is crucial. Holmatro addressed this decades ago with its New Car Technology (NCT) line of cutters.

With their innovative U-shaped blade design they are still among the highest performing hydraulic cutter options available. So, that narrows the choices. Rescuers should just choose a cutter with U shaped blades and a high score on round materials. But wait, consider this for a moment. While cutting roof pillars and hinges may be a big part of our job, what about relief cuts and cutting structures too large for our cutter to surround?

U-shaped NCT blades pull themselves towards the material which in this way will end up in the cutting recess, where it can be cut at the highest possible force.

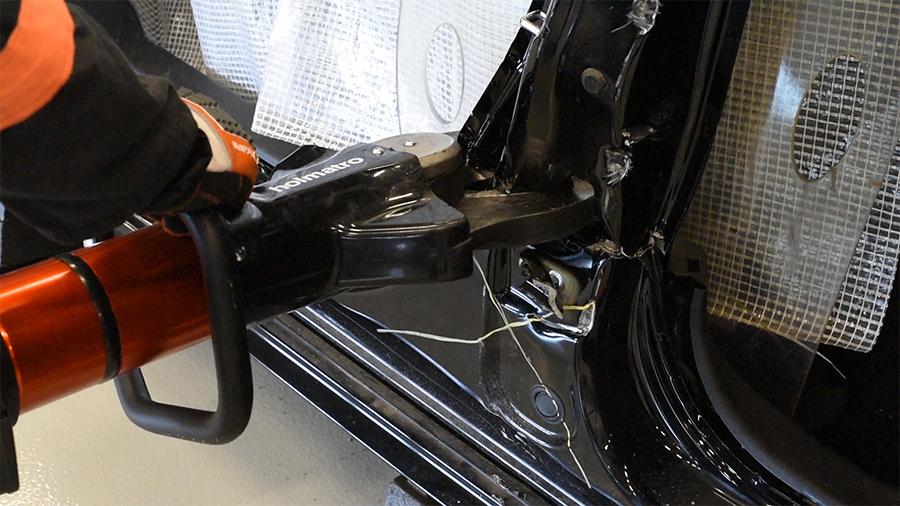

Penetrating Cuts

Right, we need a cutter that can penetrate as well. Manufacturers walk a delicate line. Design a tool that scores high on materials it can surround, but also has the strength so that the tips can penetrate through high strength materials. If the blades are too long, low tip force will cause the tool to stall instead of cutting into a structure. This could be the lower A pillar when trying to make a relief cut, or a wide B pillar. Both of these could be just as important to the rescue that you are on as cutting a roof pillar.

The ability to make penetrating cuts (strength on the blade tips) is just as important as the ability to make surrounding cuts. Both may be required during your rescue operation.

Speed

The list of requirements goes on. As a rescuer, you want your tools to be fast as well. You need to cut whatever you are working on at the moment quickly. Think again about that overall design. One cutter may cut a post a few seconds quicker than the other brand. However, does it have the tip strength to penetrate structures? Which tool is better overall for your needs?

Future proof?

Final ly, what about longevity? How long will the cutter you choose work for you? When will vehicle construction and materials exceed its capability? The only way this can be evaluated is by looking at the tool’s internal pressure when cutting. Each brand of tool has a maximum operating pressure. This is the pressure needed inside the cylinder to create the highest forces when cutting, which are also relative to the size of the cylinder and the surface area on the piston (F = p x A). The internal pressure needed to make a cut, compared to manufacturers’ highest operating pressure, will show you how future-proof your tool is. One brand of cutter may cut a post quickly, but at 80% of its maximum operating pressure, while the other brand is a few seconds slower but uses only 40-50% of its available pressure (and force!). That tells us that the cutter has a lot of power in reserve for tomorrow’s vehicle designs. Most rescue tool manufacturers can demonstrate these pressures to you by using traditional corded tools with in in-line pressure gauges alongside the same models battery driven tools.

ly, what about longevity? How long will the cutter you choose work for you? When will vehicle construction and materials exceed its capability? The only way this can be evaluated is by looking at the tool’s internal pressure when cutting. Each brand of tool has a maximum operating pressure. This is the pressure needed inside the cylinder to create the highest forces when cutting, which are also relative to the size of the cylinder and the surface area on the piston (F = p x A). The internal pressure needed to make a cut, compared to manufacturers’ highest operating pressure, will show you how future-proof your tool is. One brand of cutter may cut a post quickly, but at 80% of its maximum operating pressure, while the other brand is a few seconds slower but uses only 40-50% of its available pressure (and force!). That tells us that the cutter has a lot of power in reserve for tomorrow’s vehicle designs. Most rescue tool manufacturers can demonstrate these pressures to you by using traditional corded tools with in in-line pressure gauges alongside the same models battery driven tools.

Watch how our 5060 Inclined Cutter only uses max. 450 bar (=62.5 %) of its full capacity when cutting the B Pillar of a late model BMW in one single cut. Average pressure: 300 out of 720 bar.

Conclusion

The bottom line is that lots of considerations must be made when evaluating tools. Especially hydraulic cutters. Setting up your evaluations so that they can be done on similar vehicles (and preferably vehicles of the newest model year available) will help. Also, asking questions

to get past theoretical forces and performance on materials not related to your task will clear your view. Avoiding speed competitions and cutting some exotic piece of building material will lead us to finding the best tool. Rescue tool selection is a decision we generally only get to make every ten years or so due to budgets constraints and other equipment needs. It is most important that we find the hydraulic tools that do the best overall, on every type of accident we might face, and that will maintain this ability for many years to come.

I welcome your feedback in the comments!

Jason Bell

Southern Regional Manager Holmatro USA