New Car Technology Update

It’s always good to update what we know and learn new things as well. I am in a very lucky position to spend a lot of my time travelling and researching issues related to extrication, so of course I am not going to keep this information to myself!

Latest Vehicle Construction

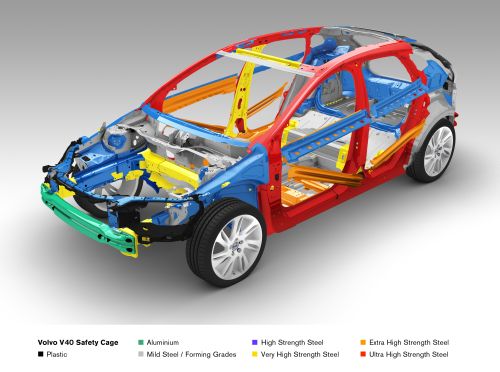

In February 2014 I visited Volvo in Sweden. I did the factory tour which was very interesting, but the most valuable part of the visit for me was meeting with their engineers and of course cutting their new model vehicles. Cutting new vehicles is something all rescuers want to do. Of course during most extrications they get the chance, but as that is a dynamic situation, actually studying the construction and material is very often not possible. The main reason rescuers like to cut new cars of course is the ‘challenge’. How strong is it? What can we do? And more importantly, what can’t we do? The internet is full of pictures like we see here:

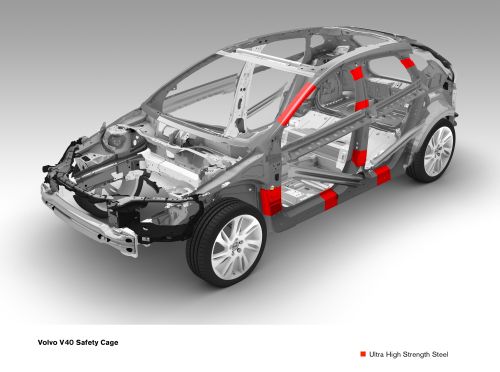

But to a rescuer, what does this mean? What does it tell you? From the point of view of underpinning knowledge, it is good to see how new vehicles are constructed. However, my belief is that these kind of pictures offer very little practical help at all, unless we can relate them to exactly what we do. So, what I tried to do whilst at Volvo I took a brand new V40 and made strategic cuts in the areas most appropriate for rescue (see picture below) and measured the pressure.

I used a Holmatro CU 4050 NCT cutter and ALL of the cuts used less than half the capacity of the tool. If you look closely, ALL of the cuts are in the Ultra High Strength Steel (UHSS) areas (see pictures above and below).

Remember, it is not so important that the tool used less than half of its capacity to complete these cuts. What is important, is that there is still more than half of the capacity of the tool in reserve.

Panoramic Glass

The last 5 years have seen an increase in the number of vehicles sold with panoramic roofs and I know it is only a matter of time before they become the next hot topic in extrication. But lets look at what they actually mean. Increased glass in the roof is good for the rescuer. In an extrication from a vehicle on its wheels, the roof can still be removed in the normal way. If a vehicle comes to rest on its side, it may be possible to extricate without folding the roof down. It will certainly offer more options in terms of initial access and space creation (see picture below).

In terms of standards, the glass must conform to Europe; ECE R43 and U.S; FMVSS205. However there is no requirement that stipulates the type of glass that is used. I have found (through a quick internet search) that the panoramic roofs themselves tend to be laminated, but where a section is designed to be opened (or slid back) this tends to be toughened (tempered). There are two issues that I think will affect the design in the future. Firstly the Roof Crush Test in the USA and secondly the increased requirement (again USA) to reduce occupant ejection in the case of a rollover. The bottom line is that it is simply more glass to deal with. It is either laminated or toughened (tempered) and we all have the tools and skills to identify and deal with that. I think the most important thing here is to be aware of the presence of panoramic roofs and take every opportunity to use them to your advantage.

As always I welcome your feedback!

Ian Dunbar