Jacking up the A12 viaduct

Lifting a viaduct over the A12 highway to replace the bearing pads under the box girders. Commissioned by Spanbeton, Holmatro supplied 150 tonnes locknut cylinders.

Commissioned by: Spanbeton

Location: A12 highway, Netherlands

SITUATION

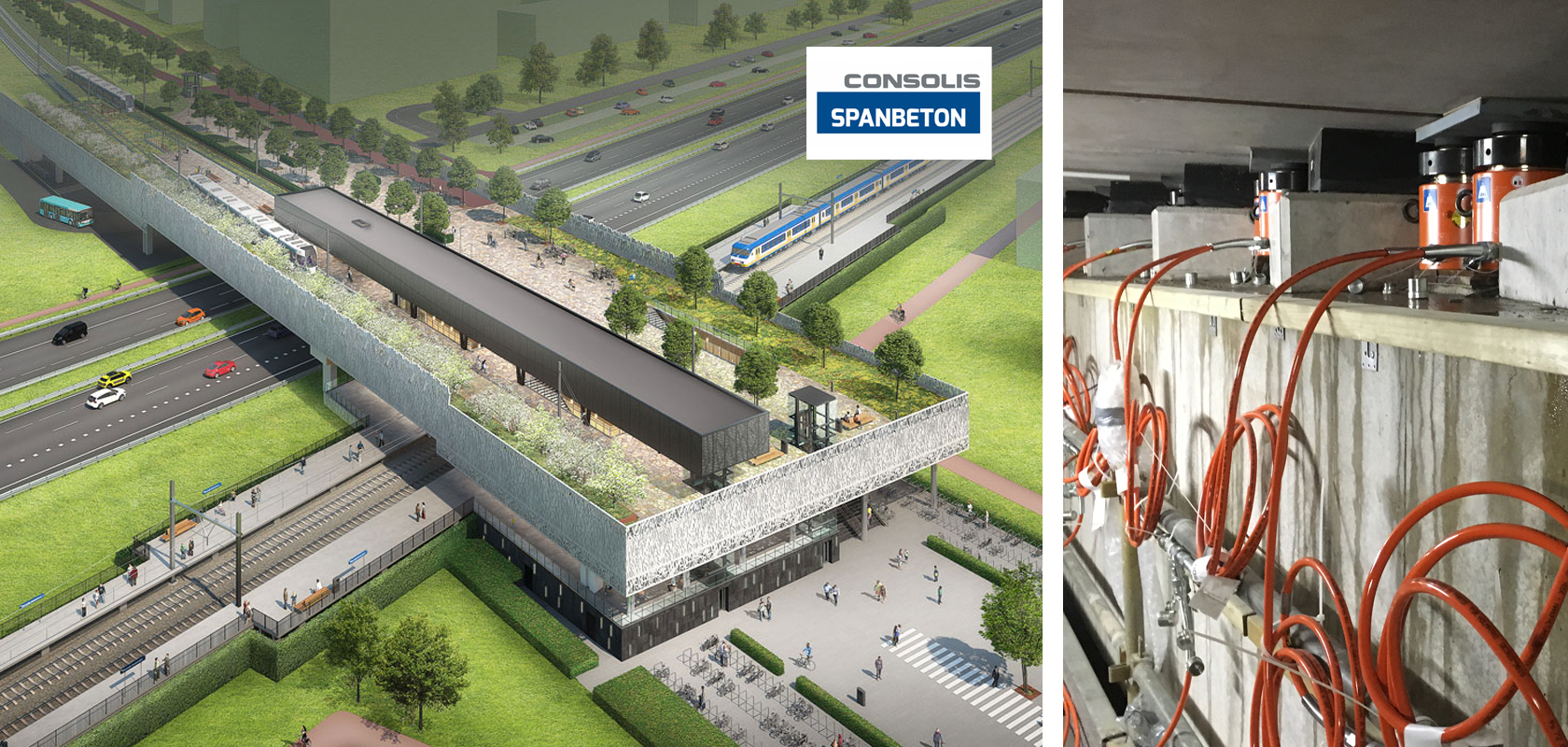

At the end of 2018, the cities of Zoetermeer and Lansingerland will have a unique transport hub: Bleizo. Trains, RandstadRail rapid transit trains and trams, buses, cars and bicycles will be joined together with a viaduct over the A12 highway near the Lansingerland-Zoetermeer train station. The platform has a sustainable, green design and will have space for 700 parking spots; room for some 10,000 travelers per day has been taken into account.

CHALLENGE

The construction of the structure for the A12 viaduct was trusted to contractor VOBI B.V. from Vinkeveen (NL). Spanbeton was commissioned by VOBI to produce and assemble the prefab box girders used for the main bridge spans above the highway.

Because the bridge span was not allowed to 'touch' the road, the use of a middle support in the shoulder was not permitted. This resulted in box girders of 61 meters long, each weighing 172 tons. Special bearing pads were placed under the box girders to absorb expansion and shrinkage, caused by temperature differences. During construction, these bearing pads had to be replaced, which meant that the entire overpass had to be jacked up.

SOLUTION

To skillfully and safely lift the viaduct, Holmatro has developed 50 double-acting locknut cylinders, each with a capacity of 150 tonnes. The locknut cylinders had a tilting saddle in order to absorb irregularities in the construction and were simultaneously controlled by a 400V Vari pump.

Would you like to know more about this project? Contact us via e-mail [email protected] or call +31 (0)162 751500.